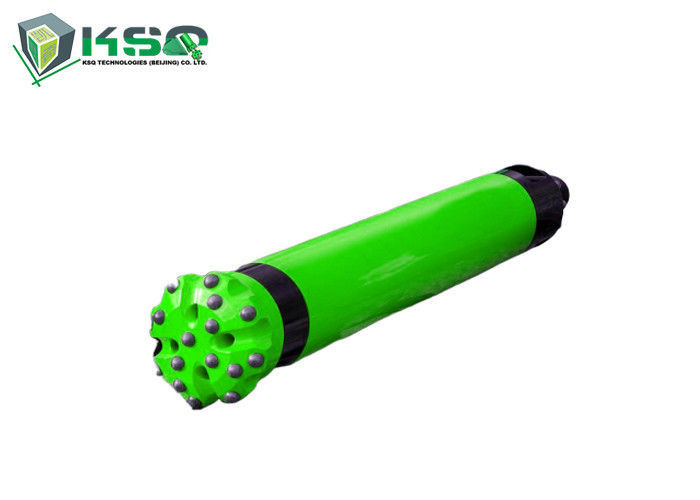

Drilling hole from 165 to 190mm DHD360 COP64 D65 6 inch Hammers For mining and construction

FEATURES

MIROC offers one of the most complete lines of down the hole drills and downhole bits ranging from 3.5” – 36” (89mm – 914mm) which are designed for peak performance in all rock drilling applications including but not limited to; foundation & geotechnical drilling, blasthole drilling in quarries & mines, waterwell & geothermal boreholes, oil & gas underbalanced drilling, horizontal directional drilling, and utility transmission & distribution rock sockets.

Selecting the right hammer

The optimum range of hole size for DTH drilling is 90 mm (3.5”) to 254 mm (10”). Smaller holes are generally drilled using tophammer drill rigs, and larger holes generally use rotary drill rigs.

Advantage

• Industry leading steerability

• Outstanding rate of penetration

• Simple design allows for field maintenance

• Reduced air requirement results in lower cost per foot

• More efficient and durable internal design

• High frequency operation of rock drills provides less vibration

Technical Manual of DTH Hammer

|

Low Pressure

DTH Hammer

|

Model |

Drilling

Diameter

(mm)

|

Hammer

Length

(mm)

|

External

Diameter

(mm)

|

Working

Pressure

(Mpa)

|

Air

Consumption

(m3/min)

|

Torque

(N.m)

|

Impact

Frequency

(n/min)

|

| 1 |

DTH65B |

ø68 - 70 |

745 |

ø61.2 |

0.5 - 0.7 |

2.5 |

51 |

≥810 |

| 2 |

DTH70 |

ø72 - 74 |

803 |

ø67.2 |

0.5 - 0.7 |

3 |

70 |

≥810 |

| 3 |

DTH76 |

ø74 - 76 |

766 |

ø67.2 |

0.5 - 0.7 |

3 |

75 |

≥810 |

| 4 |

DTH80 |

ø80 - 82 |

796 |

ø72 |

0.5 - 0.7 |

5 |

81 |

≥800 |

| 5 |

DTH80-II |

ø75 - 80 |

756 |

ø67 |

0.5 - 0.7 |

3 |

75 |

≥810 |

| 6 |

DTH80X |

ø80 - 82 |

756 |

ø72 |

0.5 - 0.7 |

4.5 |

75 |

≥800 |

| 7 |

DTH80XD |

ø80 - 90 |

735 |

ø74 |

0.5 - 0.7 |

5.5 |

85 |

≥800 |

| 8 |

DTH90 |

ø90 - 130 |

796 |

ø80.2 |

0.5 - 0.7 |

6 |

110 |

≥820 |

| 9 |

DTH90-I |

ø90 - 130 |

796 |

ø80 |

0.5 - 0.7 |

5.5 |

120 |

≥820 |

| 10 |

DTH110 |

ø110 - 150 |

838 |

ø98 |

0.5 - 0.7 |

11 |

180 |

≥830 |

| 11 |

DTH150 |

ø150 - 185 |

908 |

ø137 |

0.5 - 0.7 |

17 |

340 |

≥800 |

| 12 |

DTH170 |

ø170 - 250 |

1023 |

ø156 |

0.5 - 0.7 |

19.5 |

420 |

≥790 |

|

High Pressure

DTH Hammer

|

Model |

Drilling

Diameter

(mm)

|

Hammer

Length

(mm)

|

External

Diameter

(mm)

|

Working

Pressure

(Mpa)

|

Air

Consumption

(m3/min)

|

Torque

(N.m)

|

Impact

Frequency

(n/min)

|

| 1 |

DTH330 |

ø82 - 85 |

867 |

ø71 |

0.8 - 2.1 |

3 - 12 |

150 |

≥800 |

| 2 |

DTH335 |

ø90 - 93 |

908 |

ø81 |

0.8 - 2.1 |

4.3 - 14.2 |

205 |

950 - 1500 |

| 3 |

DTH340 |

ø105 - 130 |

1052 |

ø92 |

0.8 - 2.1 |

3.5 - 18 |

304 |

≥800 |

| 4 |

DTH345 |

ø105 - 130 |

1034 |

ø98 |

0.8 - 2.1 |

3.5 - 15 |

335 |

≥800 |

| 5 |

DTH345K |

ø110 - 130 |

994 |

ø98 |

0.8 - 2.1 |

3.5 - 15 |

400 |

≥820 |

| 6 |

DTH350 |

ø130 - 152 |

1387 |

ø114 |

0.8 - 2.1 |

5.7 - 18 |

590 |

810 - 1470 |

| 7 |

DTH355 |

ø130 - 152 |

1220 |

ø124 |

0.8 - 2.1 |

6.5 - 18 |

700 |

810 - 1500 |

| 8 |

DTH355K |

ø130 - 152 |

1098 |

ø124 |

0.8 - 2.1 |

4.5 - 18 |

800 |

840 - 1500 |

| 9 |

DTH360 |

ø152 - 305 |

1450 |

ø136 |

0.8 - 2.1 |

8.5 - 25 |

822 |

820 - 1475 |

| 10 |

DTH380 |

ø203 - 350 |

1551 |

ø181 |

0.8 - 2.1 |

12 - 31 |

1560 |

860 - 1510 |

| 11 |

DTH3120 |

ø302 - 508 |

1934 |

ø275 |

0.8 - 2.1 |

14 - 45 |

2410 |

980 - 1446

|

Specification of DTH Bits

| Low Air Pressure DTH Bits |

| |

Type |

Diameter(mm) |

Buttons |

Flushing Holes |

| Front(No*mm) |

Gauge(No.*mm) |

| 1 |

CIR80 |

80 |

2*12, 2*12 |

6*13 |

2 |

| 2 |

CIR90 |

90 |

4*12 |

6*14 |

3 |

| 3 |

93 |

4*12 |

6*14 |

3 |

| 4 |

95 |

4*12 |

6*14 |

3 |

| 3" High Pressure DTH Bits |

| |

Type |

Diameter(mm) |

Buttons |

Flushing Holes |

| Front(No*mm) |

Gauge(No.*mm) |

| 1 |

DHD3.5 / M30 |

90 |

4*12, 2*12 |

8*12 |

2 |

| 2 |

95 |

4*12, 2*12 |

8*12 |

2 |

| 3 |

100 |

4*13, 2*13 |

8*13 |

2 |

| 4 |

105 |

4*14, 2*14 |

8*14 |

2 |

| 4" High Pressure DTH Bits |

| |

Type |

Diameter(mm) |

Buttons |

Flushing Holes |

| Front(No*mm) |

Gauge(No.*mm) |

| 1 |

DHD340 / SD4 /

QL40 / M40

|

110 |

4*14, 2*14 |

8*14 |

2 |

| 2 |

115 |

4*14, 2*14 |

8*14 |

2 |

| 3 |

121 |

4*14, 2*14 |

8*14 |

2 |

| 4 |

127 |

4*14, 3*14 |

8*14 |

2 |

| 5 |

130 |

4*14, 3*14 |

8*16 |

2 |

| 6 |

133 |

4*14, 3*14 |

8*16 |

2 |

| 5" High Pressure DTH Bits |

| |

Type |

Diameter(mm) |

Buttons |

Flushing Holes |

| Front(No*mm) |

Gauge(No.*mm) |

| 1 |

DHD350 / SD5 /

QL50 / M50

|

130 |

3*14, 4*14 |

9*16 |

2 |

| 2 |

133 |

3*14, 4*14 |

9*16 |

2 |

| 3 |

140 |

3*16, 4*16 |

9*16 |

3 |

| 4 |

146 |

3*16, 4*16 |

9*16 |

3 |

| 5 |

152 |

3*16, 5*16 |

9*18 |

3 |

| 6" High Pressure DTH Bits |

| |

Type |

Diameter(mm) |

Buttons |

Flushing Holes |

| Front(No*mm) |

Gauge(No.*mm) |

| 1 |

DHD360 / SD6 /

QL60 / M60

|

152 |

4*16, 4*16 |

8*18 |

2 |

| 2 |

155 |

4*16, 4*16 |

8*18 |

2 |

| 3 |

159 |

4*16, 4*16 |

8*18 |

2 |

| 4 |

165 |

4*16, 4*16 |

8*18 |

2 |

| 5 |

172 |

4*18, 4*18 |

8*18 |

2 |

| 6 |

178 |

4*18, 4*18 |

8*18 |

2 |

| 7 |

190 |

3*18, 5*18 |

9*18 |

3 |

| 8 |

203 |

3*18, 6*18 |

9*18 |

3 |

| 8" High Pressure DTH Bits |

| |

Type |

Diameter(mm) |

Buttons |

Flushing Holes |

| Front(No*mm) |

Gauge(No.*mm) |

| 1 |

DHD380 / SD8 /

QL80 / M80

|

200 |

6*18, 6*18 |

9*18 |

3 |

| 2 |

203 |

6*18, 6*18 |

9*18 |

3 |

| 3 |

216 |

6*18, 6*18 |

9*18 |

3 |

| 4 |

219 |

6*18, 6*18 |

9*18 |

3 |

| 5 |

222 |

6*18, 9*18 |

9*18 |

3 |

| 6 |

226 |

3*18, 5*18 |

12*18, 6*18 |

3 |

| 7 |

229 |

3*18, 5*18 |

12*18, 6*18 |

3 |

| 8 |

241 |

3*18, 5*18 |

12*18, 6*18 |

3 |

| 9 |

251 |

3*18, 6*18 |

12*18, 6*18 |

3 |

| 10 |

254 |

3*18, 7*18 |

12*18, 6*18 |

3 |

| 11 |

270 |

3*18, 8*18 |

12*18, 6*18 |

3 |

| 12 |

305 |

6*18, 8*18 |

12*18, 9*18 |

3 |

Company Information:

The MIROC® Rock Drilling Tools product line by KSQ Tecnologies (Beijing) Co.Ltd. is the result of years of advanced engineering, precision manufacturing,and dedication to the use of high quality materials.MIROC® Rock Drilling Tools are used by many drilling professionals related tomining, construction, tunneling, and quarrying projects around the globe.

KSQ Technologies (Beijing) Co. Ltd. provides exceptional technical know-how in development, production, and application. The company has adopted advanced manufacturing processes to ensure high quality steels and tungsten carbide inserts for its rock drilling accessories. Its personnel understand clients’ drilling needs, and have the service skills to recommend the right drilling tools for the job. Its experienced product developers can also create custom tools. Furthermore, the company’s development team introduces innovative products each year – tools that are rigorously tested in the field and proven to perform beyond industry expectations.

MIROC® Rock Drilling Tools include:

Top Hammer Drilling Tools

Down-the-hole (DTH) Drilling Tools

PDC Bits

Tricone Bits

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!