TT Series Ceramic Vacuum Filter Separte Liquids From Solids For Mining Field

Product Description

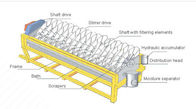

This Series Vacuum Ceramic Filter System is extensively used in the mining industry to separate liquids from solids for dewatering purpose. The operation and construction principle is similar to a conventional disc filter except the filter me-dium is replaced by finely porous ceramic discs, providing resistance to almost all chemicals and having a long operat-onal life. Can be designed and manufactured based on specific requirements by clients

Main Features

1) Filtering area from 6 cubic meters up to 120 cubic meters

2) High vacuum degree, low moisture on formed cake

3) High filtration precision, solid filtration<50ppm

4) Low energy consumption

5) Low running cost

6)Optional filter cake cleaning system

7)High degree of automation

8)Compact structure to minimize required floor space and make maintenance convenient

9)Advanced drainage system ensures application in any running condition

Applications

Can been widely used in Metral mining , such as copper, iron, gold, silver, tin, aluminum, lead, zinc, nickel, palladium, cobalt, molybdenum etc, phosphorus, coal, sulfur, silicon, quartz, mica, rare earth concentrate, tailings dewatering, Zinc Oxide, chemical industry lead oxide, zinc sulfide, electro slag, leaching slag, slag cement dehydration and environmental pollution as well as waste acid treatment.

Technical datas

| Model |

TT-2 |

TT-4 |

TT-6 |

| Specification(N m2) |

2 |

2 |

2 |

| Liquid discharging way |

Automatic liquid discharging |

Filter pump drainage |

Automatic liquid discharging |

Filter pump drainage |

Automatic liquid discharging |

Filter pump drainage |

| Size L×W×H(mm) |

2300×2480×2100 |

2300×2480×2100 |

2460×2480×2100 |

2460×2480×2100 |

2710×2480×2100 |

2710×2480×2100 |

| Outer diameter of Plate(mm) |

1510 |

1510 |

1510 |

1510 |

1510 |

1510 |

| Filter Area(m2) |

2 |

2 |

4 |

4 |

6 |

6 |

| Quantity of plate(Circle) |

1 |

1 |

2 |

2 |

3 |

3 |

| Quantity of ceramic plate(pcs) |

12 |

12 |

24 |

24 |

36 |

36 |

| Total weight(t) |

1.8 |

1.8 |

2 |

2 |

2.5 |

2.5 |

| Max Overhaul weight(t) |

0.5 |

0.5 |

0.55 |

0.55 |

0.65 |

0.65 |

| Volume of tank(m3) |

0.7 |

0.7 |

0.85 |

0.85 |

1.1 |

1.1 |

| Installed power(KW) |

6.35 |

7.9 |

7.4 |

8.95 |

7.7 |

9.25 |

| Max working power(KW) |

5.85 |

7.4 |

6.6 |

8.15 |

6.6 |

8.15 |

| Power of Spindle speed reducer (KW) |

0.75 |

0.75 |

1.5 |

1.5 |

1.5 |

1.5 |

| Power of Stirring speed reducer(KW) |

2.2 |

2.2 |

2.2 |

2.2 |

2.2 |

2.2 |

| Power of Vacuum Pump(KW) |

1.45×2 |

1.45 |

1.45×2 |

1.45 |

1.45×2 |

1.45 |

| Powere of Circulation pump(KW) |

|

3 |

|

3 |

|

3 |

| Power of Controlled Volum pump(KW) |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

| Power of Ultrasonic(KW) |

0.3 |

0.3 |

0.6 |

0.6 |

0.9 |

0.9 |

| 98%Dosage of nitric acid(kg/d) |

1.8 |

1.8 |

3.6 |

3.6 |

5.4 |

5.4 |

| Clean water(m3/h) |

0.36 |

0.36 |

0.72 |

0.72 |

1.08 |

1.08 |

| Entrance pressure of clean water(Mpa) |

0.35~0.5 |

0.35~0.5 |

0.35~0.5 |

0.35~0.5 |

0.35~0.5 |

0.35~0.5 |

| Production water consumption(m3/d) |

4.2 |

4.2 |

5.1 |

5.1 |

6.6 |

6.6 |

| Entrance pressure of production water |

0.5~0.7 |

0.5~0.7 |

0.5~0.7 |

0.5~0.7 |

0.5~0.7 |

0.5~0.7 |

| Air volume for gas back flushing(m3/min) |

0.67 |

0.67 |

0.67 |

0.67 |

0.67 |

0.67 |

| Valve control gas consumption(m3/min) |

0.36 |

0.36 |

0.36 |

0.36 |

0.36 |

0.36 |

| Air intake pressure(Mpa) |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

| Main shaft speed(r/min) |

0.5~1.5 |

0.5~1.5 |

0.5~1.5 |

0.5~1.5 |

0.5~1.5 |

0.5~1.5 |

| Speed of agitator(r/min) |

12~20 |

12~20 |

12~20 |

12~20 |

12~20 |

12~20 |

Company Information

KSQ Technologies (Beijing) Co. Ltd. is a diversified enterprise based in Beijing, China, offering a portfolio of products that help contribute to a better bottom line and increase workplace safety for the construction and mining industries.

KSQ Technologies (Beijing) Co. Ltd. has significant experience and know-how in the supply of materials, components, finished goods, specially designed/engineered equipment, and services from China. The company caters to medium to large scale clients who are doing projects and capital expansion, as well as to firms who require support with consumable products, maintenance, and repair operations. Our operations are based on the unique expertise of our people and knowledge with customer processes.

Our portfolio includes:

Consumables used in the mining and construction industries

Equipment used in the mining and construction industries

Spare parts used for the equipment we sell for the mining and construction industries

Green technologies, such as products that reduce electric consumption or use alternate sources of energy (solar, wind, etc.)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!